Back to Industry News

Cleantech

Dürr and GROB Unveil Energy-Efficient Battery Cell Production Methods

Summary generated with AI, editor-reviewed

Heartspace News Desk

•Source: ESS News

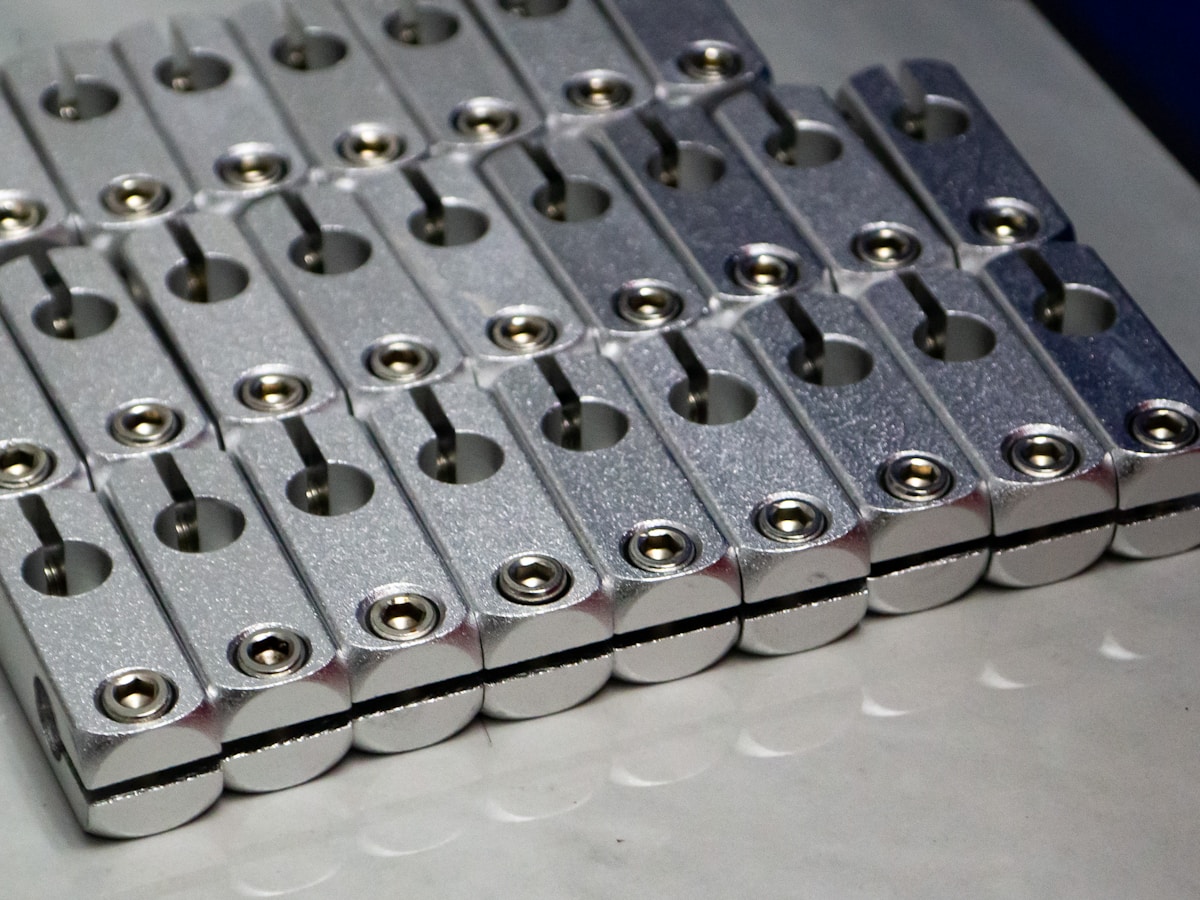

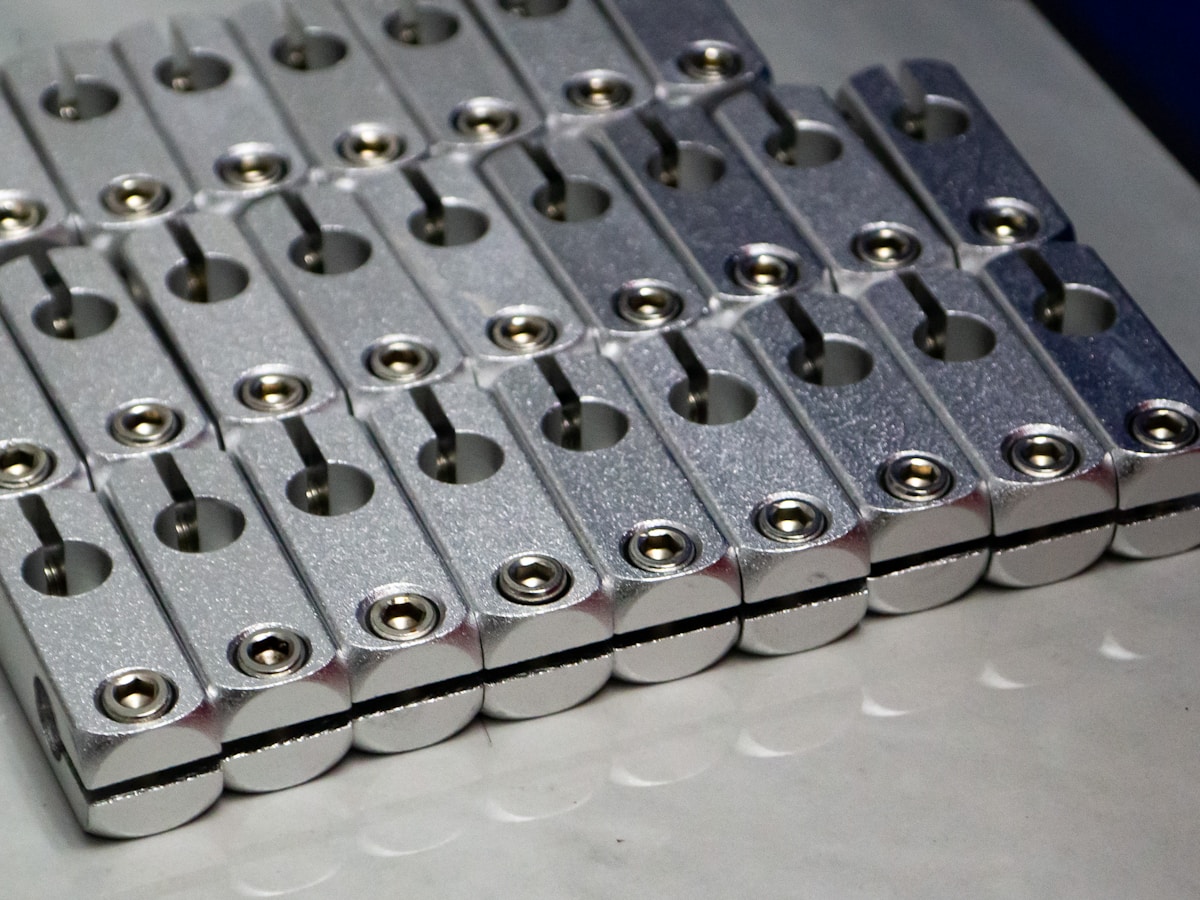

Photo by Sirius Harrison on Unsplash

Key takeaways

- Dürr and GROB introduced a factory concept targeting lower energy use in lithium-ion battery manufacturing

- The companies presented technologies at the Battery Show North America in Detroit that reduce energy consumption by 70% and facility footprint by 50%

- This new approach uses dry coating, removing the energy-intensive drying phase of conventional battery production

Dürr and GROB introduced a factory concept targeting lower energy use in lithium-ion battery manufacturing. The companies presented technologies at the Battery Show North America in Detroit that reduce energy consumption by 70% and facility footprint by 50%. This new approach uses dry coating, removing the energy-intensive drying phase of conventional battery production.

The partnership, which began in 2022, focuses on supplying battery production equipment to European and North American markets. Their X.Cellify DC product family incorporates the Activated Dry Electrode® process, improving material use and cutting waste. GROB Group CEO German Wankmiller stated their combined portfolio covers nearly the entire battery cell production value chain with proprietary technologies.

Advanced methods include high-speed cell assembly using Z-folder technology. Precise electrolyte filling at elevated pressures also increases manufacturing reliability. Dürr and GROB seek pilot partners to further develop these production technologies. The companies aim to refine battery production processes and improve resource efficiency.

Related Topics

Battery ProductionLithium-ion BatteriesEnergy EfficiencyDry CoatingCell AssemblyManufacturing Technology

Want coverage like this for your company?

Local & industry wins build trusted proof, SEO/geo signals and prime national editors.

Check fit (2 min)